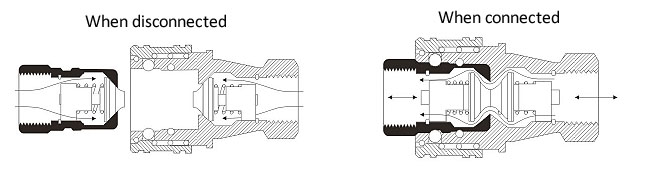

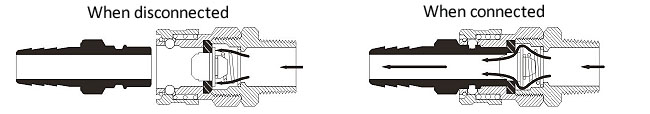

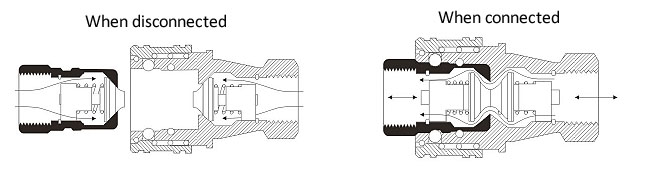

Quick couplings are devices which permit easy, immediate connections and separation of fluid and pneumatic lines. When installed in a system quick couplings saves time by eliminating the necessity to close valves, bleed the system, recharge with fluid and purge entrapped air whenever an accessory is being replaced. These couplings are commonly employed in various industries, including hydraulic systems, pneumatic systems, automotive applications, and fluid transfer processes. The primary purpose of quick release couplings is to enable swift and tool-free connections and disconnections, reducing downtime and improving overall efficiency.

Material of Contractions: 1) Carbon Steel 2) Stainless Steel 3) Brass.

Color-Coding: In some cases, quick release couplings may be color-coded to help users easily identify the appropriate coupling for a specific application or fluid type

It’s important to note that the specific design and features of quick release couplings can vary based on the intended use and industry requirements. When selecting a quick release coupling, it’s essential to consider factors such as the type of fluid, operating pressure, temperature, and other application-specific requirements.

Quick release couplings come in various types and configurations, each designed for specific applications and industries. Here are some common types of quick release couplings:

Quick release couplings find applications in various industries due to their convenience and efficiency in connecting and disconnecting fluid or gas lines. These are some common applications of quick release couplings:

Overall, the versatility and speed of quick release couplings make them valuable in a wide range of industries where fast, reliable, and secure connections are essential.

Quick release couplings play a crucial role in hydraulic systems, providing several benefits that contribute to the efficiency and functionality of these systems. Here are some specific applications of quick release couplings in hydraulic systems:

Fluid Power Equipment:

Maintenance and Repairs:

Mobile Machinery:

Emergency Situations:

Testing and Diagnostics:

Fluid Transfer:

Modular Systems:

High-Pressure Applications:

Customization and Adaptability:

Preventing Contamination:

In summary, quick release couplings enhance the functionality, versatility, and maintainability of hydraulic systems, making them an integral component in various industries and applications.